3D scanning technology

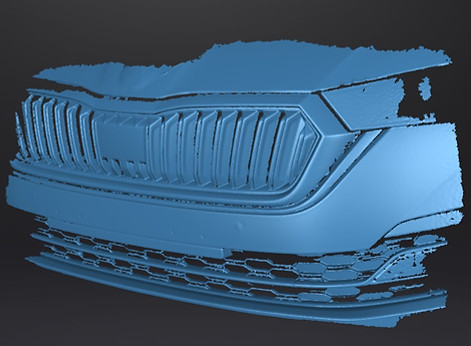

3D scanning involves creating a three-dimensional point cloud, which is then transformed into an accurate geometric model in CAD software. The scanner operator scans the surface of the element multiple times to gather a complete data set. For shiny or black surfaces, a washable coating is often applied to ensure precise data collection. The duration of the scanning process depends on the size and complexity of the object. After scanning, the collected data requires further processing to accurately recreate the geometry of the element.

Full-service scanning

.jpeg)

We offer comprehensive 3D scanning services, providing raw scans, geometry recreation, and production of elements based on scanned data using our manufacturing technologies.

Depending on your needs, we create elements tailored to the scanned object's geometry, such as mounts, brackets, covers, or vehicle parts.

Our service includes storage of elements provided for 3D scanning, as well as the option to travel to the client. Additionally, you can send the item for scanning via courier.

Finishing

We offer production of both prototype and final elements based on 3D scans, with surface finishing included. Our components are precisely matched to the shape captured by 3D scanning technology. We can also introduce modifications to enhance your components.

Our additional services include:

-

painting,

-

insertion of threaded inserts

-

application of 3M foam,

-

sealing.

Explore our custom plastic component production services tailored to meet your individual needs. Contact us to learn more and place an order.